-35% Time saving

through automatic calculation & documentation

-25% Cost

through shorter projects &

better processes

100% more transparency

for all involved in

each planning step

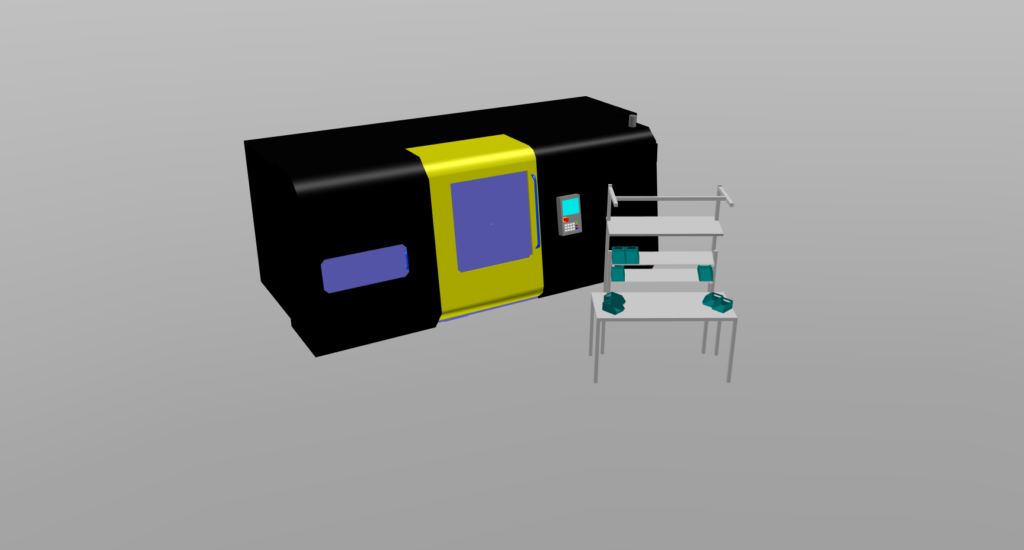

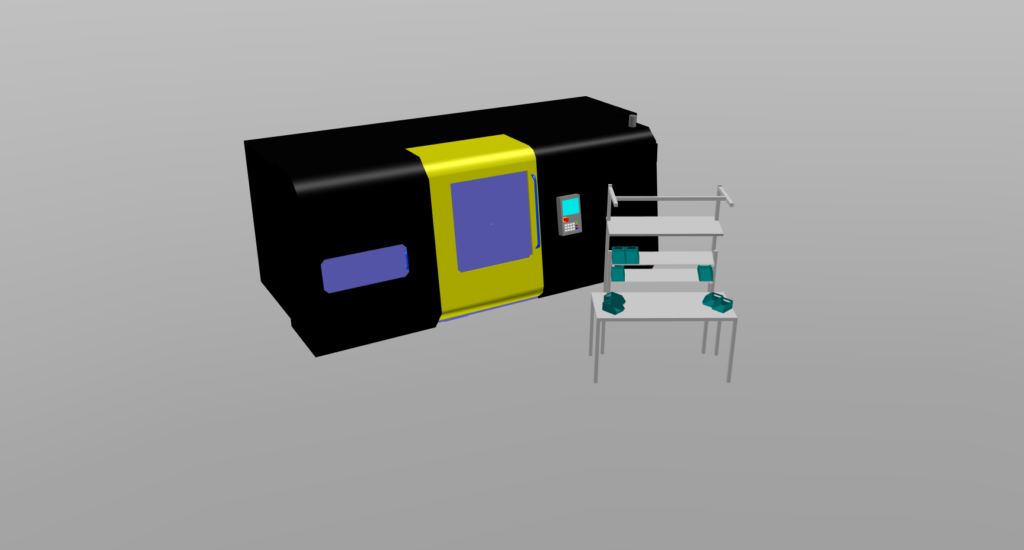

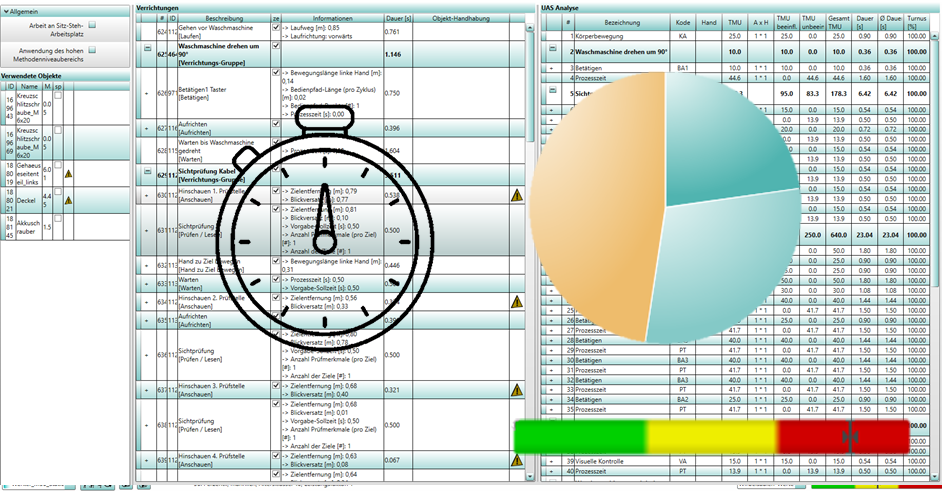

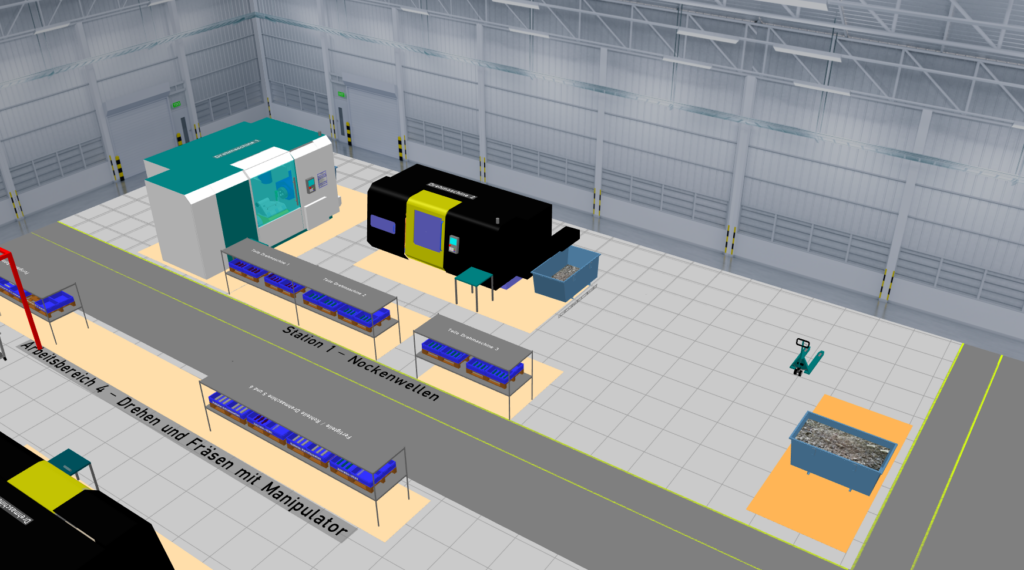

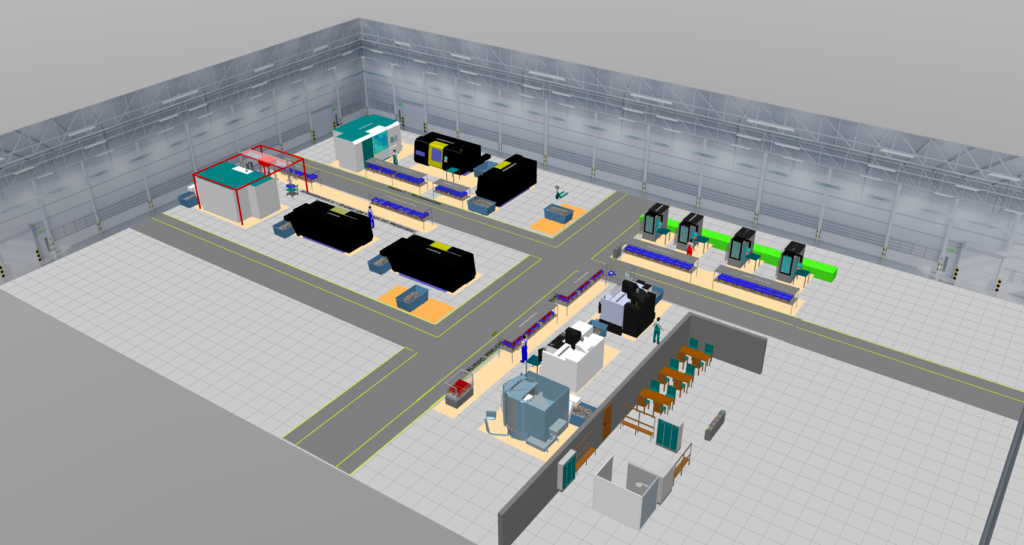

Planning, assessment and 3D simulation of human work in the context of the digital factory.

With ema Work Designer, workplaces and production processes can be designed in detail, manual activities and human-robot system sequences can be visualised and complete manufacturing and assembly processes can be simulated in 3D. In combination with the integrated analysis and evaluation of time and ergonomics in relation to standard performance (e.g. MTM-UAS and EAWS), valid and plausible planning results for reliable processes are automatically generated.

You are currently seeing a placeholder content of YouTube. To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information

Arrange a free demo without obligation now.

The 2 steps to your demo licence:

Tip: Take advantage of a free live demonstration & make it easier for yourself to get started with our free ema Academy