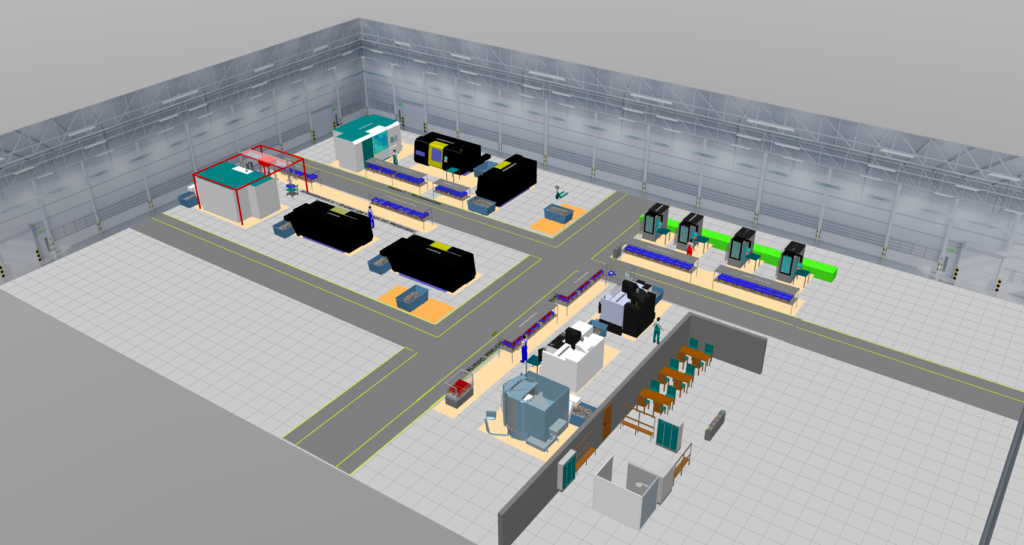

-30% Surface

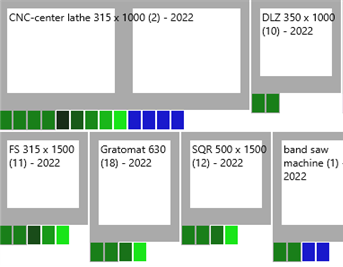

Efficient use of space

& resources through optimisation of material flows & buffer areas

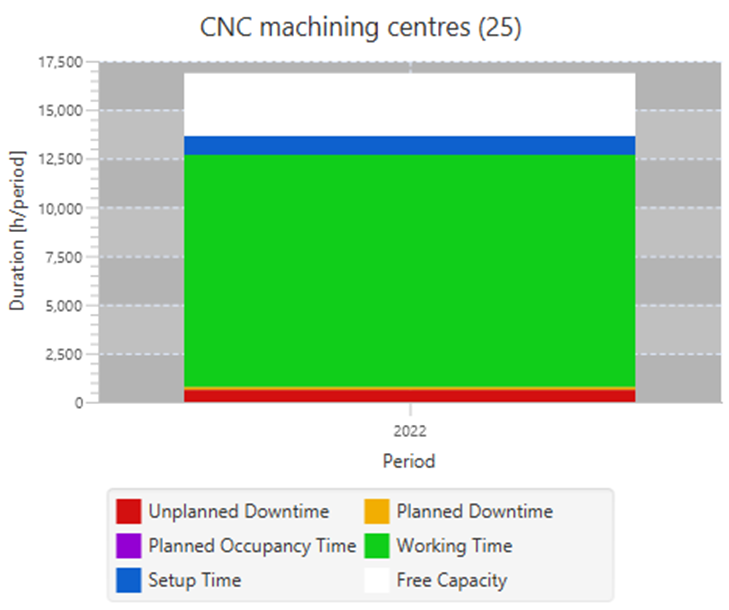

+25% Productivity

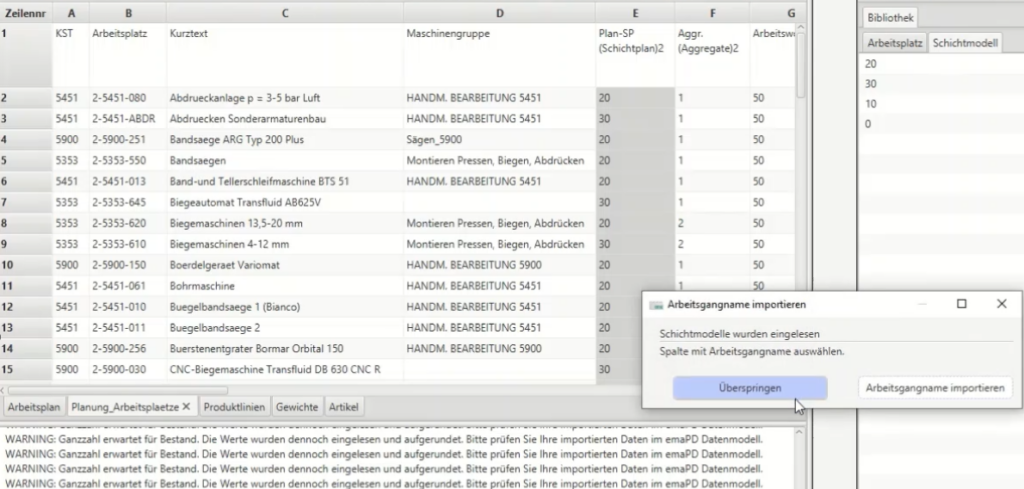

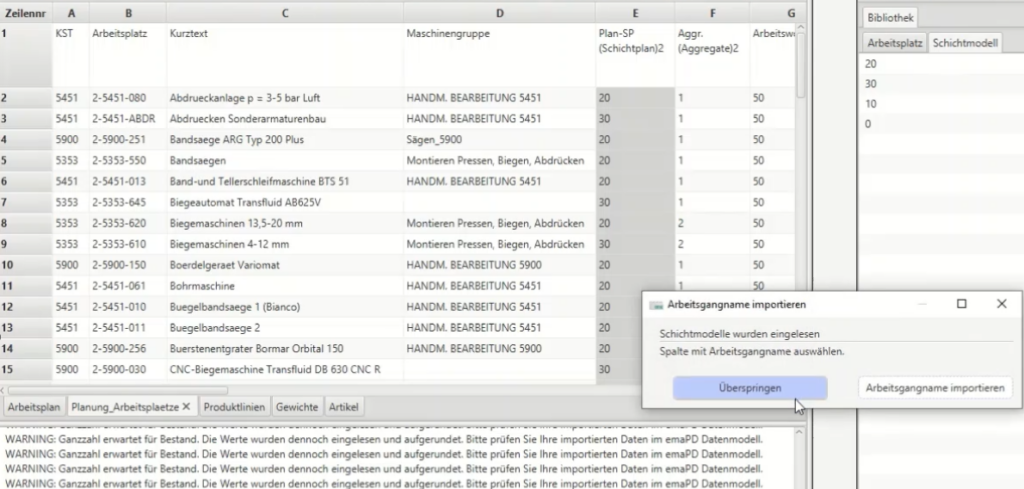

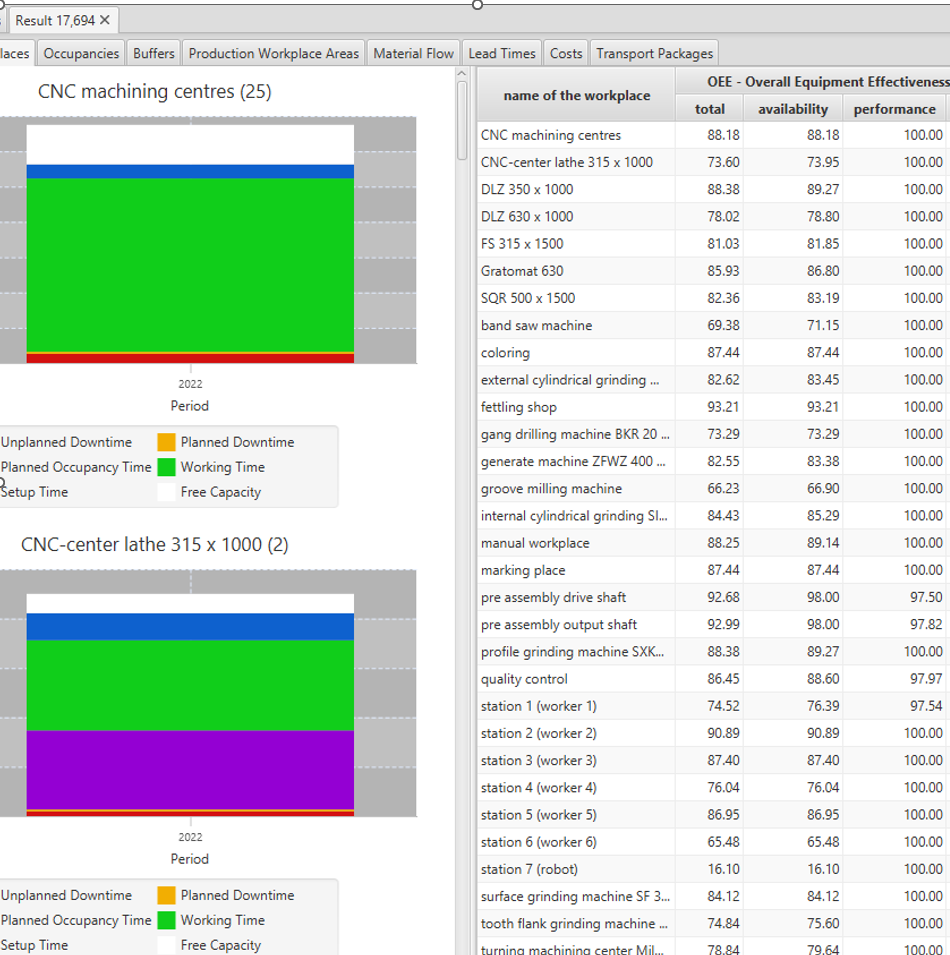

Optimisation of capacity utilisation incl. bottleneck identification incl. calculation of required resources

-20% Cost

Determination of measures through analysis of material, manufacturing and

& Current inventory costs

The ema Plant Designer enables the simple, quick and precise planning and Evaluation from Production processes with the aim of developing lean and highly efficient production.

The software offers the best of the worlds of simulation & value stream and delivers robust results on Capacity utilisation of jobs incl. Bottleneck analysis, Production costs, Lead times and critical paths, Buffer locations and Manufacturing space, Material flows and Resource consumption – independent of type and Size of the use case

Arrange a free demo without obligation now.

The 2 steps to your demo licence:

Tip: Take advantage of a free live demonstration & make it easier for yourself to get started with our free ema Academy