Digital tools for healthy and productive workplaces in industry

The challenges in production planning are growing: product diversity, shorter life cycles, ageing workforces and the shortage of skilled labour call for well thought-out solutions - especially in industries with a high proportion of manual activities.

The design of ergonomic, productive workplaces is becoming a key factor here: not only to reduce the sickness rate (see blog post "Reduce sickness rate"), but also to ensure quality, optimise production times and be perceived as an attractive employer (de Looze et al., 2010; Falck et al., 2010).

Ergonomics as a success factor

Well-designed workstations have added value: fewer bending movements, more favourable gripping spaces or reduced physical strain can shorten production times, enable employees who have undergone performance changes to be deployed - and improve overall economic efficiency (Lawaczeck, 2001; Landau et al., 2003; Neubert, 2013).

The preventive view in the planning phase is particularly crucial. Instead of optimising existing workstations retrospectively (corrective ergonomics), increasing emphasis is being placed on prospective design - using digital tools.

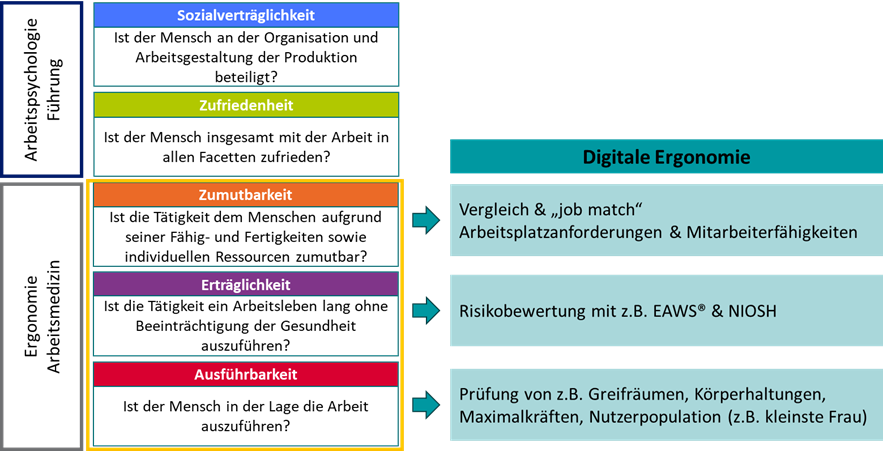

Figure 1: Levels of human-centred work design and possibilities of digital ergonomics (own illustration based on Kirchner, 1972; Rohmert 1983, Luczak & Volpert 1987).

Digital ergonomics assessment: from plan to optimised process

Digital tools such as the ema Software Suite offer the opportunity to recognise and avoid ergonomic risks at the planning stage - without the need for physical prototypes or cardboard engineering.

Ergonomically critical situations can be identified, compared and evaluated in the virtual model. On this basis, well-founded requirement specifications, technical specifications and realistic layouts are created - all along the digital twin.

Advantages at a glance

Early error preventionErgonomic weaknesses become apparent as early as the concept phase.

Cost savingsNo physical prototypes or conversions necessary.

FlexibilityExisting workstations can be digitally optimised - without disrupting production.

Holistic approachNot only the workplace, but entire processes and material flows can be designed ergonomically.

To be continued...

Part 2 of the blog post is about:

Digital human models and gripping spaces

Ergonomics analyses with EAWS® and NIOSH

Ergonomic process optimisation

Job rotation and skills-orientated workplace design