Manufacturing companies are under increasing pressure from new technologies, new competitors and stagnating markets. Customers expect more variants, while at the same time the number of units per model is falling and costs are rising. In Germany, high labour and energy costs and a shortage of skilled workers are adding to the pressure.

Three key findings

- Lean manufacturing avoids waste such as overproduction, inventories and waiting times through consistent efficiency.

- Separate fast movers from exotics using Pareto analysis to achieve harmonious batch sizes and low congestion.

- Control before the bottleneck with pull and keep set-up levels at 5 to 15% to ensure stable processes.

The challenges facing industrial production are constantly increasing. New production processes, new materials and new competitors with new products are entering the market. This increases competitive pressure, especially in a market that is only growing to a limited extent or is stagnating. At the same time, existing customers are becoming more demanding, which is why the number of variants is increasing and the number of units per variant is falling. In Germany in particular, rising manufacturing costs due to high non-wage labour costs and energy costs as well as an increasing shortage of skilled workers on the shop floor are also leading to further pressures.

Industrial companies are under increasing pressure from new competitors, rising costs and a shortage of skilled labour, while at the same time the requirements for product variance are increasing with decreasing quantities.

Company with production

This article will focus on a specific type of manufacturing company: Companies that have at least partial manufacturing processes in terms of the following characteristics:

Production of discrete articles (no process industry or chemical industry)

The manufacturing processes generally consist of primary forming (e.g. injection moulding), forming (e.g. bending), machining processes (e.g. turning) or coating processes

Various items can be produced on the workstations

When switching from one article to another, set-up times are incurred, which is why batch or order-based production must be carried out

Lean manufacturing

These manufacturing companies are increasingly confronted with the challenges mentioned above. As many of these challenges cannot be influenced, the companies' room for manoeuvre lies primarily in the Design of the production itself. This should be lean, i.e. streamlined. The idea is to continuously work on the product from the start of the production process to completion. Any waste (overproduction, inventories, transport, waiting time, time-consuming processes due to unsuitable resources, long distances, rejects/rework) must be avoided and all production factors (machines, systems, personnel, means of transport, equipment, tools, materials) must be used efficiently.

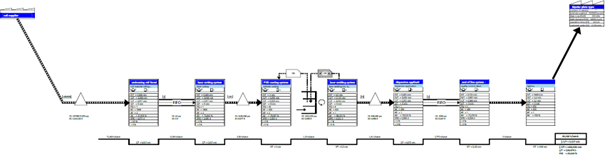

As a tool for visualising the production processes, the Value stream as it can be used to quickly gain an overview of the key figures (see Figure 1).

Concrete options for action

For manufacturing companies, this raises the question of how to avoid waste and what to look out for. The following options for action focus on ways to Avoidance of overproduction, stocks and waiting times as well as the use of suitable resources.

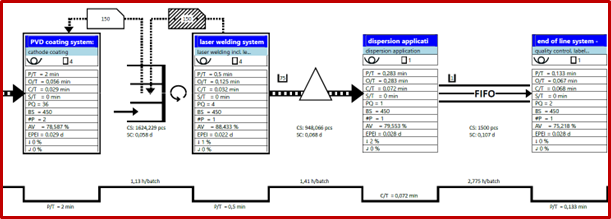

First of all, it is necessary to know exactly which products are manufactured, i.e. to find out which products are fast movers and which products are exotic, for example with the help of a Pareto analysis (see Figure 2).

This is necessary because the way in which fast-moving and exotic items can be processed efficiently differs. While fast-moving items are characterised by high quantities and a certain regularity in customer call-offs, the predictability in terms of quantity (order size) and regularity of an exotic item is low. The regularity of customer call-offs for fast-moving items offers the opportunity to produce in production batch sizes determined by the company itself, irrespective of customer orders. The main difficulty therefore lies in the definition of the optimal batch sizes.

Lean manufacturing means systematically avoiding waste and consistently utilising resources efficiently, from overproduction to rejects and rework.

Before these can be defined, it is necessary to check whether a physical separation of exotic and high-speed items makes sense, i.e. whether it is possible to use different machines and systems for the production of exotic and high-speed items. If all items are produced at one workstation, the processing sequence will include high-speed and exotic items, i.e. long and short production times (sum of set-up time and processing time of a batch) alternate. This leads to a „traffic jam“ in front of the work centre and therefore to high stock levels and long throughput times. In contrast, a Separation of exotics and fast movers the definition of harmonised production batch sizes only for high-speed production runs (the document duration of a production batch is very similar for all high-speed production runs), which leads to lower inventories and shorter throughput times.

Another starting point that needs to be considered when defining the optimum batch sizes is the Bottleneck process. This has an influence on both the batch size and the control system. Depending on the utilisation of the bottleneck process and the degree of set-up (proportion of set-up time to occupancy time), an initial estimate of the harmonious, optimum production batch size can be derived for high-speed production. The rule of thumb here is The setup level should not exceed 15% and not fall below 5%, The higher the capacity utilisation, the lower the degree of set-up. This rule of thumb provides a good ratio of machine and setter utilisation on the one hand and space consumption for the transport aids/containers on the other. It is not possible to make a general statement on the optimum degree of set-up, but always requires a company-specific assessment.

Differentiating between fast-moving and exotic products is key to effective lean measures, because both product types require different planning, batch sizes and control logics.

Also from the point of view of Production control the bottleneck work centre can be regarded as decisive. It therefore makes sense to control all processes upstream of the bottleneck work centre with pull, while all downstream processes can (but do not have to) be controlled with push. This prevents a backlog from forming before the bottleneck and ensures that there is only a maximum of one production batch size (=KANBAN batch size) of each fast-moving item before the bottleneck process. Only when the stock is reduced due to a withdrawal before the pull-controlled work centre is a production order in the amount of the defined production batch for the previous work centre triggered.

Digital problem solving with the ema Plant Designer

As the interrelationships described above are interdependent and often complex, manual analyses quickly reach their limits. This is precisely where the ema Plant Designer in order to solve these tasks not only faster, but also in a more profound way.

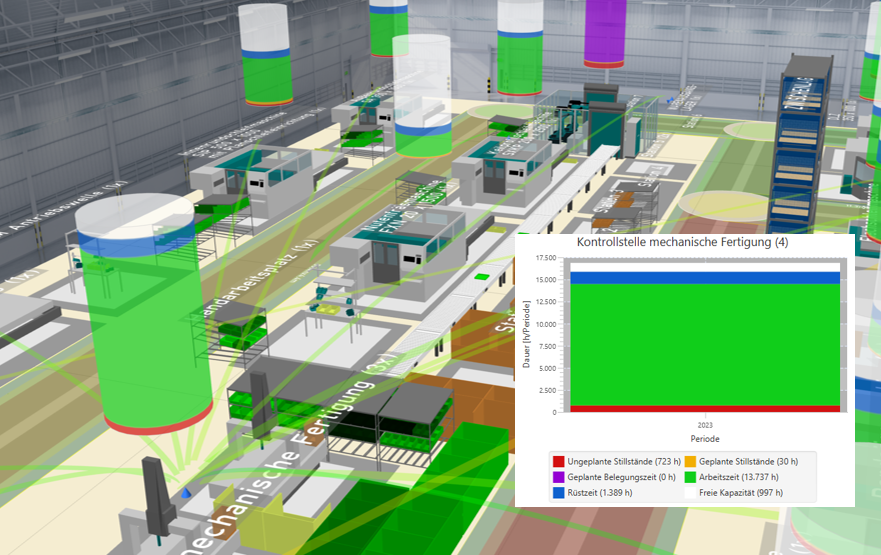

Instead of relying on structural calculations, the ema Plant Designer enables a dynamic simulation of your production scenarios. It combines the best of the worlds of simulation and value stream analysis. This allows you to test the effects of separating fast-moving and exotic items or changing batch sizes in a digital twin before you go into physical implementation.

The advantages of digital processing at a glance:

- Precise bottleneck analysis: The software automatically identifies bottlenecks and visualises the utilisation of workstations so that you can target control measures (push vs. pull) where they will have the greatest effect.

- Optimisation of space and resources: Intelligent planning of material flows and buffer areas can save up to 30% of space and increase productivity by up to 25%.

- Cost transparency: ema Plant Designer provides you with reliable figures on manufacturing costs and work in progress, allowing you to directly evaluate cost reduction measures (potential up to -20% costs)

With this software support, you can transform complex lean principles into a manageable, digital planning process that works regardless of the size of the use case and gives you confidence in your decisions.

Summary & conclusion

To optimise the ever-increasing challenges In order to master the challenges of industrial production, it is necessary to streamline production and avoid waste. When implementing specific measures, it makes sense to differentiate between so-called fast-moving and exotic products. Depending on the quantity distribution or regularity of the various products, different control principles and adapted production batch sizes help to avoid inventories, waiting times and overproduction.

Suitable software solutions such as ema Plant Designer are the decisive lever here. They not only help you to analyse the effects at an early stage, but also make the complexity manageable. By digitally validating planning scenarios, you can secure your long-term competitiveness and realise efficiency potential that would remain hidden if you looked at it manually.

The bottleneck and setup level are the levers for stable flows, sensible batch sizes and a control system that limits stocks before the bottleneck, for example using pull principles.

FAQ

What is the goal of lean manufacturing in one sentence?

The goal is a continuous flow of value with minimal waste, so that throughput times are reduced and productivity increases.

Which types of waste should companies address first?

Focus on overproduction, inventories and waiting times because they directly increase throughput times and capital commitment and often trigger chain effects.

Why do I have to categorise my products into fast movers and exotics?

Because fast movers are easier to plan and are more suitable for standardised, harmonised batch sizes, while exotics are more order-driven and less predictable.

What are the benefits of physically separating high-speed and exotic products in production?

It reduces the risk of congestion and changing occupancy times at a workstation, which typically reduces stock levels and throughput times.

What role does the bottleneck play in batch size and control?

The bottleneck sets the pace, so it makes sense to control upstream processes with pull and limit stocks, while downstream processes can run more with push.

Arrange an appointment now Non-binding consultation for lean manufacturing. We will show you how to use the ema Plant Designer Streamline your production and produce more efficiently tomorrow.

Andreas Opitz

Head of Factory and Logistics Planning