While classic ergonomics consulting often resembles a one-off check - with a clipboard, folding rule and biros - virtual ergonomics offers a permanent view of realityOnly digital, objective and scalable. The analysis is not just carried out once, but can be repeated, varied and even integrated automatically thanks to the virtual planning solution - a decisive difference to conventional methods.

Human factor, software factor

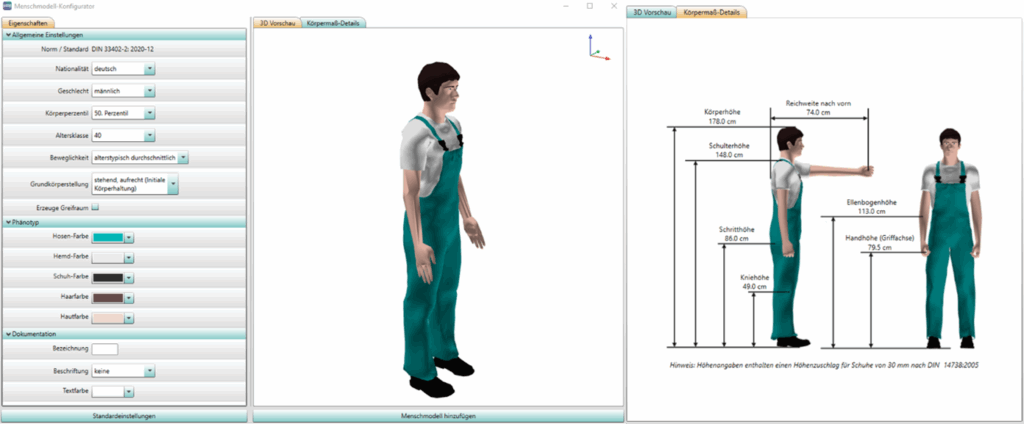

In a real workplace test, only the test subjects who are currently standing in the room can be assessed. In the virtual world, people can be in all its diversity small, large, female, male, young, old.

This means that companies can be inclusive and resilient plan - and later optimise in a targeted manner.

This creates real flexibility in the design: if a workstation is available to several people, it can be checked in advance whether it is suitable for a particular person. usable for all and beneficial to health instead of having to make costly retrofits at a later date.

Figure 2: ema Work Designer "Human model configurator" with various setting options (left) and precise details of the body part dimensions (right).

Optimising the design of reach-in spaces

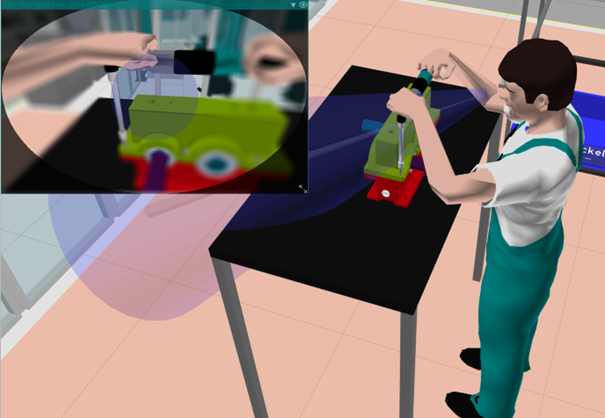

Once the user population has been selected, the ema Work Designer can be used to visualise the 2D and 3D reach space (Figure 3) in accordance with DIN 14738:2005 and the literature on ergonomics (Hettinger & Wobbe, 1993).

The use of 2D and 3D gripping space templates enables a quick analysis of ergonomically favourable gripping spaces for the optimum arrangement of material, containers and equipment in the work system.

Figure 3: 3D reach space with zoning according to ergonomic findings (Hettinger&Wobbe, 1993).

Ergonomics - but with KPIs, please

What does "good" mean? In virtual ergonomics, there are no vague gut feelings about this.

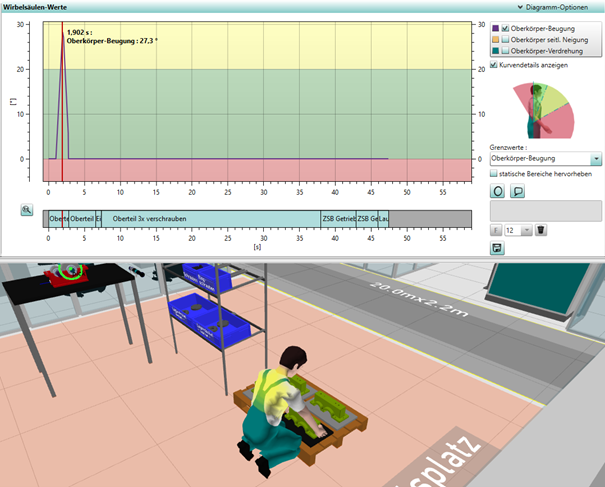

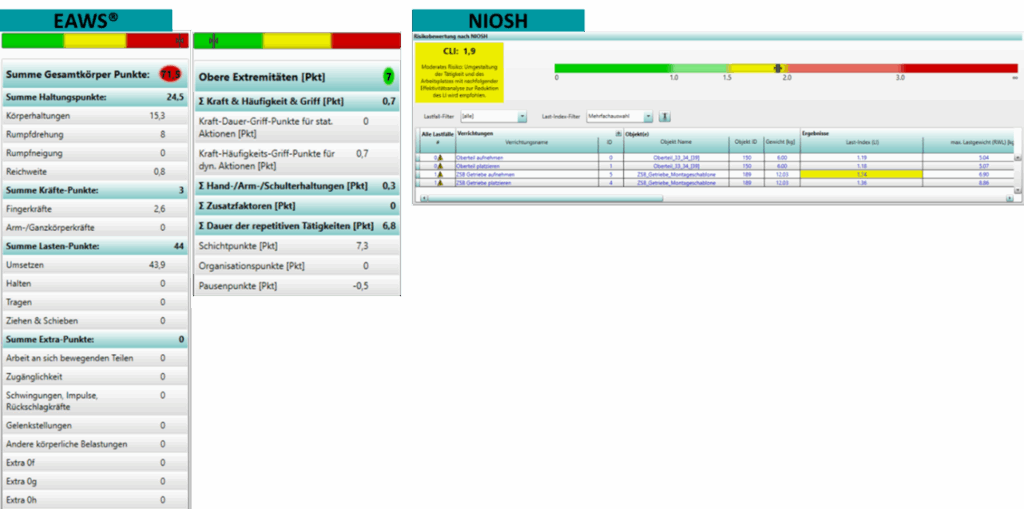

Instead: Objective, quantifiable evaluation systemse.g. RULA, NIOSH, EAWS or the REFA scheme. The software evaluates stress situations automatically - and uses heat maps, ratings or simple scores to show where risks arise.

Figure 4: Analysis of posture according to DIN EN 1005-4 (torso bending angle in diagram representation (top) and as body part colouring according to risk area in 3D (bottom).

Figure 6: EAWS® assessments (total body and upper extremities (left side) and NIOSH procedure (right side).

Simulation ≠ Gimmick

Virtual ergonomics sounds futuristic - but it's not a game.

It is a tool for Error prevention, process improvement and risk minimisation.

Especially in times of demographic change and a shortage of skilled labour, ergonomics is becoming a competitive factor.

Companies that invest in low-stress workplaces at an early stage benefit in the long term: through higher productivity, less downtime - and not least through improved employer attractiveness.

Ready for Smart Workplaces

The integration of virtual ergonomics data into digital twins, MES systems or HR reporting is not a dream of the future. It is possible today - with tools such as ema Work Designer or comparable software solutions. The data is not only visualised, but can also be integrated into existing Integrate decision-making processes - for example as part of tenders, rescheduling or investment decisions.

Conclusion: those who plan virtually today will save in real terms tomorrow.

Ergonomics is not a nice-to-have. It is measurable, effective and economical - when it is thought digitally.

And the best thing is that virtual ergonomics is scalable. From a workstation for one person to a global rollout across hundreds of plants.

This makes it a strategic component of sustainable, healthy and future-proof production.